What is Industrial Analytics?

The core competency behind Industry 4.0

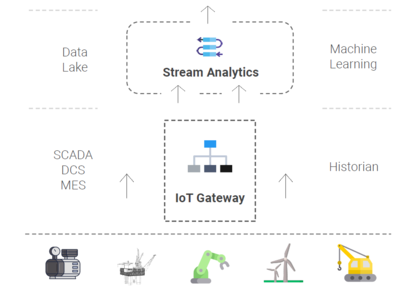

INGEST, COMBINE & VISUALIZE ALL PLANT DATA

Think beyond process historians. Collect asset and process data into a central data store. Combine it with production data to visualize the complete picture.

PREDICT & OPTIMIZE PLANT OPERATIONS USING ML-AIDED APPS

- Optimize energy consumption using product benchmarks

- Drive equipment availability through online condition monitoring

- Achieve process stability by proactively detecting anomalies

BUILD CUSTOM SOLUTIONS SPECIFIC TO YOUR PROCESS

For example,

- Build & deploy a Predictive Quality model that can catch defects upfront

- Configure advanced monitoring dashboards and alarms